Need Assistance?

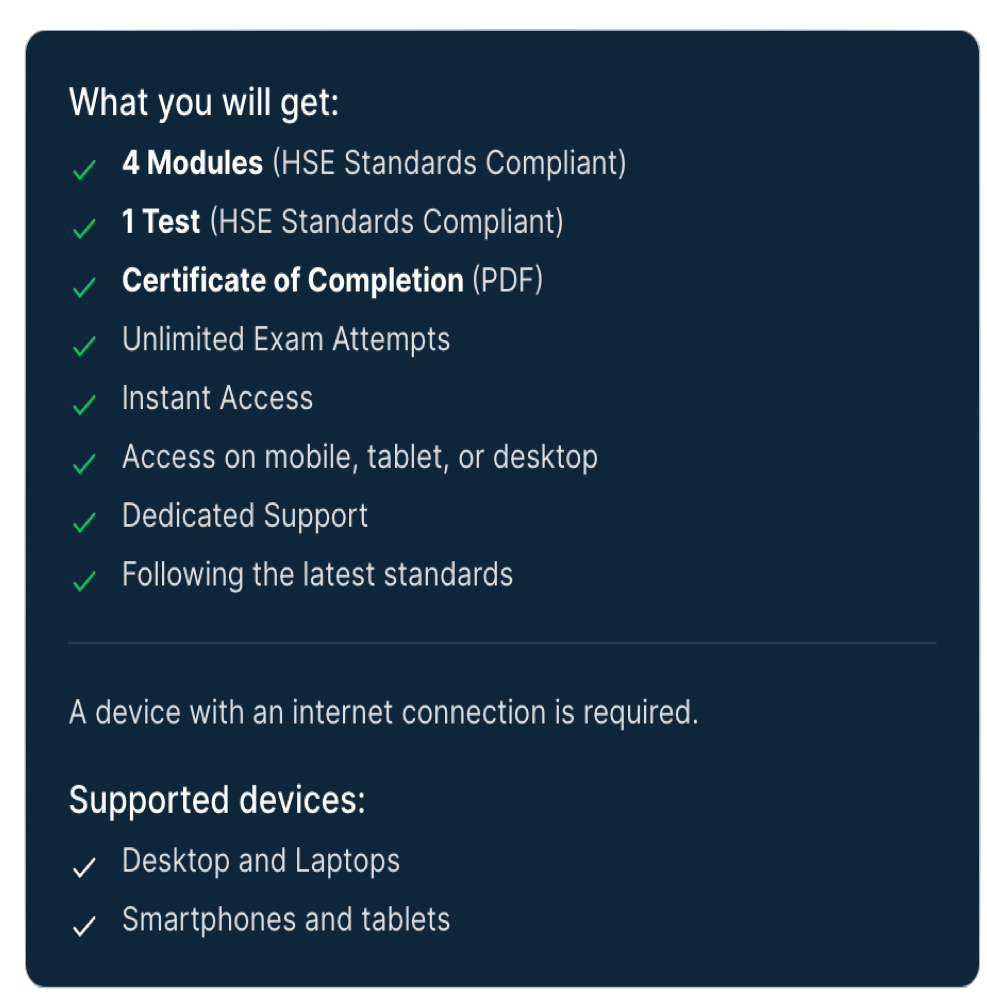

| Quantity Discounts | per course |

| 1 to 5 courses: | £21 |

| 6 to 10 courses: | £19 |

| 11 to 20 courses: | £16 |

| 21 to 50 courses: | £14 |

| 50+ courses: | £12 |

Safety Ireland Ltd is a premier provider of straightforward, efficient, and user-friendly occupational health and safety training resources in Ireland, EU and the UK. Our certifications are recognized across Ireland, UK and EU.

Complies with the latest Health and Safety Authority (HSA) regulations.

ur certifications are recognized across Ireland, the UK, and the EU.

The Course is delivered by NFQ-approved instructors at FETAC Level 6 (acknowledged by QQI)

Your Certificate includes your name, company name (if applicable), name of course taken, name of your instructor, date of completion, expiry date and stamps of approval or accreditations by recognised authorities.

Our e-learning courses are 100% online, making it easy for you to get the training that you and your company need, either in your spare time or at work and at any time of day. Bigger orders = better discounts. The courses have no time limit for completion so you can take full advantage of your training.

Large enterprise orders above 500 courses are dealt with on a case-by-case basis. This includes a tailor-made package to suit your needs, with some of the following benefits:

To discuss any of your training requirements and budget in more detail, please contact our friendly sales team on +35319203720

Asbestos is an extremely hazardous substance that causes serious ill-health to anyone who disturbs or damages it. For this reason, all workers who may come across asbestos or asbestos-containing materials (ACMs) must be trained so that they can work safely. This includes work with potential ACMs, accidental discovery of asbestos, and accidental damage to asbestos and ACMs.

This IATP accredited Asbestos Awareness (Category A) course provides a comprehensive introduction to the dangers of working with asbestos. By taking our training you will be complying with the Control of Asbestos Regulations 2012. You will understand what asbestos is and where you may encounter it, the dangers associated with asbestos exposure, and what to do if you discover asbestos. This knowledge will help you or your team to stay safe around asbestos.

This course has been updated and is legally accurate in line with any guidance changes that have resulted from Brexit legislation - including any revisions to deadlines.

Our accredited Asbestos Awareness (Category A) course is designed for anybody who works with, or near, asbestos at work. This includes the following job roles:

Please note that as this is a Category A Asbestos Course, the information in this course is an awareness level of training. It does not allow you to work with asbestos or conduct asbestos removal. Such work requires practical training additional to this course.

| Module | Description | |

|---|---|---|

| 1 | Introduction | In the first module of this course, we will provide you with a comprehensive introduction to asbestos awareness. We will explain what asbestos is, how you may disturb it during your work and the risks to your health from asbestos exposure. |

| 2 | The Control of Asbestos Regulations |

This second module explains the main requirements of the Control of Asbestos Regulations 2012 (the CAR 2012) and how they apply to dutyholders. |

| 3 | Health Risks and Personal Factors |

In the third module, we will explain the health complications that arise after exposure to asbestos. You will learn about asbestos-related diseases, Workplace Exposure Limits and your requirements for respiratory protective equipment. |

| 4 | Discovery of Asbestos or Accidental Disturbance of ACMs |

In the final module, we will examine the dangers of disturbing asbestos. You will learn what to do if you discover asbestos unexpectedly, if you accidentally disturb Asbestos Containing Materials and the emergency procedures that you must follow. |

By completing this training, you will understand:

After completing the four modules, you will be invited to take the course assessment. This is made up of 20 questions and will test the knowledge you have gained from your training. The questions are multiple choice and are marked automatically, so you will instantly know whether you have passed. The pass mark for the assessment is 90% and you can take it as many times as you need to with no extra charge.

Nearly half of all accidents resulting from abrasive wheels happen due to unsafe working practices and operator errors. If you work with abrasive wheels then following strict health and safety practices is paramount to protect both yourself and others from harm.

This Abrasive Wheels course will provide you with an introduction to working safely with abrasive wheels so that you can understand the risks and know which control measures are needed to prevent injury and ill-health.

Who Should Take This Course?

This course is suitable for anyone who uses abrasive wheels in their work activities. The course is particularly relevant for those who use bench grinders, pedestal grinders and angle grinders. Although the training doesn't cover the use of specialist grinding machines, the health and safety information throughout the course is still applicable. This course has been written at an introductory level and no pre-requisite training is required. Experience of using abrasive wheels would be advantageous.

This certified online training is ideal for people working in positions such as, but not limited to:

Engineer

Builder / Floor Layer / Bricklayer

Electrician

Carpenter / Joiner / Fitter

Site / Project Manager

Welder

| Module | Description | |

|---|---|---|

| 1 | Introduction to Abrasive Wheels |

Types of abrasive wheels, dangers of abrasive wheels, abrasive wheels and the law, manufacturers responsibilities, employer responsibilities, employee responsibilities, HSE guidance. |

| 2 | Risk Assessment |

What is a risk assessment?, who should carry out a risk assessment?, Step One: Identifying hazards, Step Two: Decide who might be harmed and how, Step Three: Evaluate the risks, Step Four: Record the findings, and Step Five: Review and update. |

| 3 | Safe Practices for Abrasive Wheels |

The hierarchy of control, wheel speed, wheel handling and storage, wheel mounting, mechanical guards and work rests, safe working practices, inspections and checks and safely dressing abrasive wheels. |

| 4 | Further Abrasive Wheel Hazards and Controls |

Prevention of eye and face injuries, harmful dusts, vibration control, noise reduction and control, fire risks, electrical safety, hand-held grinding and cutting-off tools, training, communication and monitoring, Reporting of Injuries, Diseases and Dangerous Occurrences Regulations 2013 (RIDDOR), first aid and emergency procedures. |

The online assessment is taken on completion of the training material. You will be asked 20 multiple choice questions with a pass mark of 80%. The answers are marked automatically so you will instantly know whether you have passed. If you don't pass don't worry! You can take the test as many times as you need with no extra charge.

This Manual Handling Training Course helps employers ensure that they and their employees are sufficiently trained in the principles and practices of safe manual handling.

This course provides the necessary information and training for organisations to understand more about the risks associated with manual handling, how to undergo a risk assessment and how to ensure appropriate control measures are put in place.

It follows the requirements of the Manual Handling Operations Regulations 1992 (MHOR) and provides a practical guide for managing and carrying out safe and healthy manual handling. The course also features videos, diagrams, and downloadable resources to use in your workplace.

The manual handling course is aimed at employees at all levels who may undertake manual handling operations, including the transporting of a load of items by lifting, lowering, pushing, pulling, carrying, manoeuvring, steadying or transporting thereof by hand or by bodily force. This includes, but is not limited to, professions such as:

| MODULE | DESCRIPTION | |

|---|---|---|

| 2 | Manual Handling Injuries | Types of injury, immediate injuries and musculoskeletal disorders. |

| 3 | Risk Assessments for Safe Manual Handling | What is a risk assessment?, who should carry out a risk assessment?, identifying hazards, TILE, factors that increase the risk of harm, deciding who may be harmed and how, occupations most at risk, evaluating risks, recording the significant findings, reviewing and updating, results of your risk assessment. |

| 4 | Avoiding and Controlling the Risks | Employer duties, avoiding manual handling, reducing the risk, team handling, mechanical and automation precautions, personal protective equipment and TILE. |

| 5 | Safe Manual Handling Techniques | Lifting and lowering techniques, safe weights for lifting and lowering, carrying, risk assessments and HSE tools, pushing and pulling, and team handling. |

Upon completion of this course, you will:

The online assessment is taken on completion of the training material. You will be asked 10 multiple choice questions with a pass mark of 80%. The answers are marked automatically so that you’ll instantly know whether you passed. If you don't pass don't worry! You can take the test as many times as you need with no extra charge.

Falls from height are one of the most common causes of injury at work. They can result in serious injuries and fatalities to people at work and others passing by, including those carrying out construction and maintenance as well as members of the public. Therefore, it's important that anyone carrying out work at height activities understands how to work safely and responsibly and in accordance with the law.

This Working at Heights training course helps you to comply with the Working at Heights Regulations by providing employers and employees with the necessary information needed to be able to successfully deal with working at height risks and control measures. This includes an understanding of how to undertake a working at height risk assessment to effectively control and manage risks, how to use access equipment safely and how to ensure that employees can reduce their risk of falls from height.

Who Should Take This Working at Heights Training Course?

Anyone who works at height in any place, including a place at or below ground level, is required to undertake training to prove that they are competent and safe in their work.It is the employer’s duty to ensure that this training is provided: Regulation 5 of the Working at Heights Regulations that employers must ensure all employees engaged in any work at height activity must be competent to do so. This includes, but is not limited to, professions such as:

Aims of the Working at Heights Training

By the end of this course learners will be able to:

| The online assessment is taken on completion of the training material. You will be asked 20 multiple choice questions with a pass mark of 80%. If you don't pass don't worry! You can take the test as many times as you need with no extra charge. |

|---|

This Fire Safety Training course teaches you about the various types of fire extinguishers and the techniques for using them. It explains how to assess the situation if a fire starts, such as determining the class of fire and deciding whether you should or shouldn’t fight it.

It also contains infographics and videos to illustrate how different extinguishers look and operate, as well as practical exercises throughout to test your knowledge of techniques. On completion of the course, you will feel confident to use extinguishers or a fire blanket safely and effectively during an emergency.

Who Should Take This Course?

This course is designed for the designated fire wardens or marshals in a workplace. While it is not a replacement for practical training in how to use fire extinguishers (which all fire wardens / marshals must receive), our course can be taken as an introduction to using fire extinguishers before you undergo practical training, as well as a refresher after receiving practical instruction.

Practical fire extinguisher training is typically refreshed every 3 years, so this course can act as a useful reminder in between your practical sessions. It'll solidify your knowledge and give you the confidence to use an extinguisher safely in an emergency.

Aims of the Training

By the end of this course, you will understand:

| The online assessment is taken on completion of the training material. You will be asked 20 multiple choice questions with a pass mark of 90%. If you don't pass don't worry! You can take the test as many times as you need with no extra charge. |

|---|

A thorough understanding of health and safety is essential in all workplaces, regardless of job role and industry. This accredited Level 2 Health and Safety course ensures that you understand the most common health and safety risks in your workplace and the control measures that are needed to keep you safe.

The course covers the most crucial aspects of health and safety that are present in every workplace, such as manual handling, working at height, and fire and electrical safety. It also explains the necessary components of workplace welfare, including workplace stress and conflict.

| Module | Description | |

|---|---|---|

| 1 | Risk Assessment |

What is a risk assessment, who should carry out a risk assessment, identify the hazards, decide who might be harmed and how, evaluate the risks and decide on controls, record your findings, and review and update the risk assessment. |

| 2 | Workplace Safety |

Safe systems of work, slips, trips and falls on the same level, falls from height, housekeeping, electrical safety, and fire safety. |

| 3 | Workplace Welfare |

Welfare facilities, first aid, first aid safety signs, workplace stress, drugs and alcohol, and workplace conflict and violence. |

| 4 | Manual Handling and Display Screen Equipment |

Manual handling regulations, reducing manual handling risks, good manual handling techniques, display screen equipment, and workstations. |

| 5 | Hazardous Substances and Working at Height |

Hazardous substances control measures, hazardous substances training, hazardous substances safety signs, working at height, control measures, working at height equipment, and safe use of ladders and stepladders. |

| 6 | Noise, Vibration and Vehicle Safety |

Noise elimination, reduction, and control, Hand-Arm Vibration Syndrome (HAVS) and Carpal Tunnel Syndrome (CTS), employer responsibilities, safe use of vehicles, and pedestrian-vehicle conflict. |

This Level 2 HACCP course will introduce learners to the Hazard Analysis and Critical Control Points management system and help you to understand how to comply with the law, how to work safely and efficiently and what each crucial step of the HACCP implementation process entails.

By the end of the course learners will have a thorough understanding of why HACCP is important, how the 7 HACCP principles can be implemented and what can be done to ensure the food handled in their business remains safe for the consumer.

Who Should Take This Course?

This Level 2 HACCP course is suitable for employees at all levels within a food business. This includes full-time, part-time and temporary workers.

The course aims to provide a comprehensive introduction to HACCP and teaches learners about what they can do to help their business implement the system and comply with the law.

| Module | Description | |

|---|---|---|

| 1 | Introduction to HACCP |

What is HACCP? Key terms, legislation, benefits of HACCP and enforcing the law. |

| 2 | Food Safety Hazards |

How contamination applies to HACCP, physical, chemical, microbial and allergenic contamination and cross contamination. |

| 3 | Principles and Prerequisites |

The 7 principles, examples of prerequisites, effective prerequisites and assessing prerequisites. |

| 4 | Creating a HACCP System |

The basics of HACCP, creating a HACCP team, describing the products and ingredients, identifying the products’ uses and consumers, constructing a flow diagram and confirming the flow diagram. |

| 5 | The 7 Principles: Hazard Analysis and Control Measures |

The 7 principles of HACCP, hazard analysis, determining critical control points, the codex decision tree and establishing critical limits. |

| 6 | The 7 Principles: Monitoring and Verification |

Monitoring critical control points, establishing corrective actions, establishing verification procedures, reviewing the HACCP plan and record keeping. |

| The online assessment is taken on completion of the training material. You will be asked 20 multiple choice questions with a pass mark of 80%. If you don't pass don't worry! You can take the test as many times as you need with no extra charge. |

|---|

,

Hello there.

How can we help?